The Efficiency of an Optical Fibre Diameter Analyser in Reducing Manufacturing Errors

Wiki Article

Just How an Optical Fibre Diameter Analyser Boosts Quality Assurance in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser right into Fibre production processes stands for a significant improvement in top quality control methodologies. By using real-time, specific measurements of Fibre diameters, this modern technology resolves the important demand for uniformity in manufacturing requirements.

Importance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is crucial in the area of optical Fibre modern technology, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, attenuation, and general transmission effectiveness. Precision in measuring Fibre Diameter makes certain that the optical properties are maintained within defined resistances, which is crucial for optimum signal honesty.Variants in Fibre Diameter can bring about raised losses as a result of spreading and modal dispersion, impacting the top quality of information transmission. In high-speed interaction systems, such inconsistencies can lead to significant degradation of signal top quality, causing data errors and lowered efficiency. Furthermore, constant Fibre Diameter is vital for compatibility with connectors and splicing technologies, which are indispensable parts of Fibre optic networks.

Quality assurance processes in Fibre production greatly count on accurate Diameter dimensions to ensure conformity with industry criteria. By executing durable measurement strategies, producers can boost product reliability, decrease waste, and enhance total system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it works as a foundation in the improvement of optical Fibre innovation and its applications in modern-day communication networks.

Exactly How the Analyser Functions

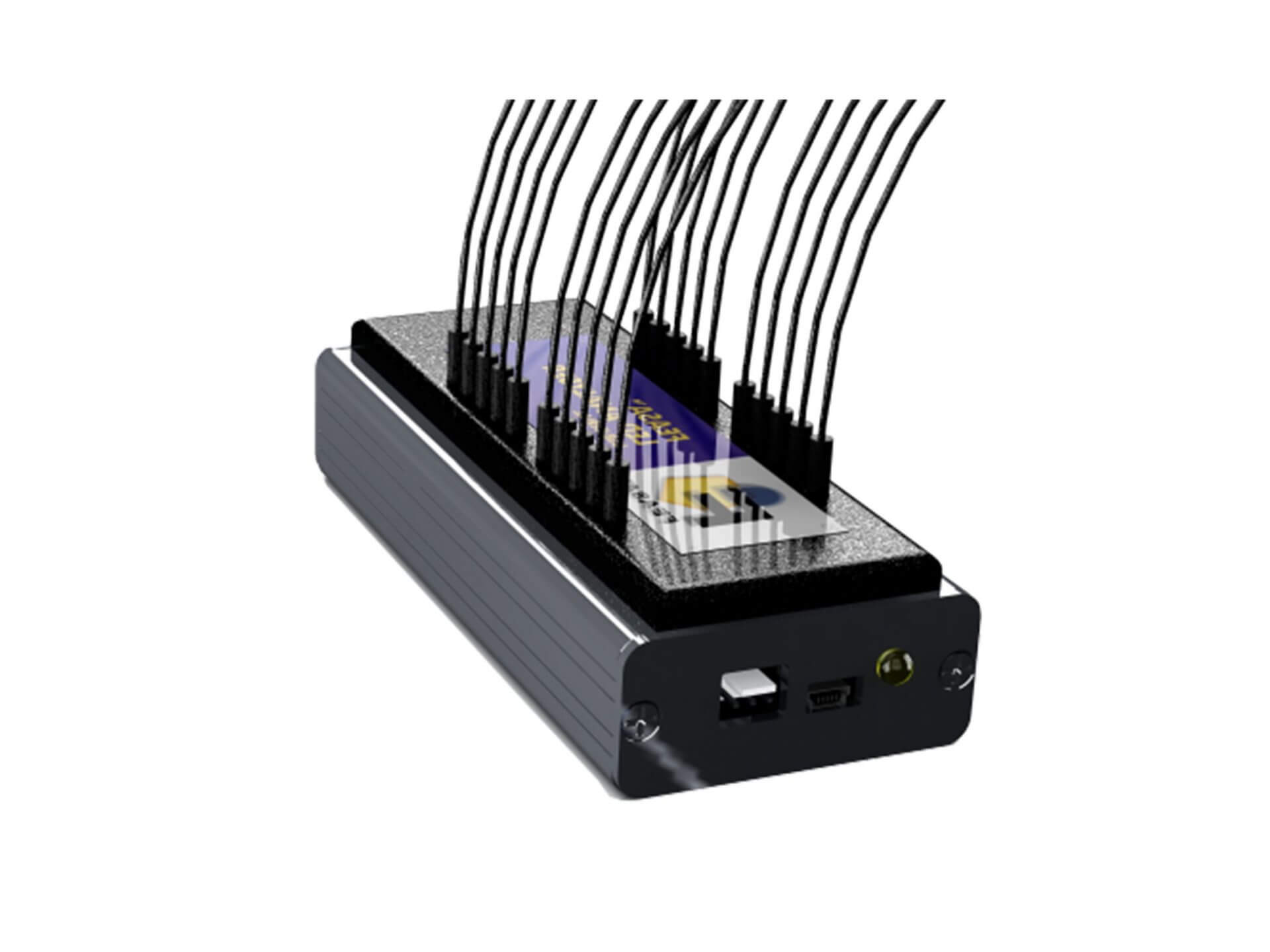

The effective dimension of Fibre Diameter depends on innovative analytical strategies that guarantee accuracy and reliability in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed image processing formulas to properly evaluate the Diameter of fibers as they are generatedInitially, a laser beam of light is guided at the relocating Fibre, producing a cross-sectional darkness. The analyser records this shadow utilizing high-resolution cams placed strategically along the production line. The caught pictures are after that refined in real-time to identify the Fibre's Diameter with outstanding precision.

The system utilizes sophisticated algorithms that represent different variables, including variants in light strength and ecological conditions, to improve dimension integrity. It can identify minute changes in Diameter, such as fluctuations that might occur during the manufacturing process.

Additionally, the analyser can managing several fibres at the same time, enhancing throughput without compromising precision. By giving immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays a critical duty in preserving strict quality assurance criteria, making certain that the end product fulfills market specs and customer needs.

Benefits of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter frequently entail lengthy post-production checks, real-time monitoring significantly improves the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This positive approach permits suppliers to determine deviations in Fibre Diameter as they happen, rather than waiting up until manufacturing is total to analyze high qualityBy continually determining the Diameter during manufacturing, producers can make certain that the fibres fulfill stringent specs, leading to minimized variability and boosted consistency. Real-time tracking additionally allows prompt corrective actions to be taken, decreasing waste and avoiding malfunctioning fibers from entering the supply chain.

Moreover, this innovation facilitates boosted data collection and evaluation, providing insights into production patterns and prospective areas for enhancement. Such data-driven decision-making encourages manufacturers to optimize processes and keep high standards of quality control.

Additionally, real-time tracking cultivates a culture of continuous improvement within the manufacturing setting. Staff members are extra engaged when they can see the impact of their job in real-time, leading to enhanced accountability and a commitment to excellence. Generally, the execution of real-time monitoring systems in optical Fibre manufacturing converts to premium item top quality and raised customer satisfaction.

Effect On Production Efficiency

Executing optical Fibre Diameter analysers dramatically boosts manufacturing performance by simplifying the production process. These gadgets help with continuous monitoring of Fibre Diameter, enabling makers to spot inconsistencies in real-time. By determining disparities quickly, production lines can be readjusted promptly, lessening downtime and decreasing the possibility of producing defective products.In addition, the assimilation of these analysers into the production operations allows much better source allowance. With precise Diameter dimensions, operators can maximize material use, making certain that resources are not thrown away on problematic fibres. This accuracy also adds to much less rework and junk, eventually reducing production costs.

The automation supplied by optical Fibre Diameter analysers reduces dependence on manual examinations, which are prone and typically time-consuming to human mistake. Consequently, workers can concentrate on more critical tasks, boosting overall efficiency.

Moreover, the data created from these analysers can educate process renovations and help with far better decision-making. By analyzing patterns in Fibre Diameter variations, makers can apply aggressive procedures to boost production methods and keep regular quality. In summary, optical Fibre Diameter analysers play a crucial function in enhancing manufacturing performance, resulting in higher top quality result and increased success.

Study and Success Stories

Throughout various industries, study highlight the transformative impact of optical Fibre Diameter analysers on production processes. One famous instance is a leading telecoms firm that encountered obstacles with irregular Fibre diameters, causing boosted denial prices. By incorporating an optical Fibre Diameter analyser, the business accomplished real-time tracking of Fibre dimensions, resulting in a 30% decrease in flaws and substantial price financial savings.

Moreover, a research establishment focusing on innovative products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's capability to give comprehensive understandings into Fibre consistency allowed the development of cutting-edge products with better performance characteristics.

These success Website stories emphasize the vital role of optical Fibre Diameter analysers in improving top quality control, enhancing manufacturing efficiency, and driving advancement throughout diverse sectors.

Conclusion

In verdict, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control view it within Fibre production. As demonstrated through various case studies, the analyser proves important for achieving superior product quality in Fibre production.

The execution of optical Fibre Diameter analysers allowed for rigid high quality control, making certain that the investigate this site generated fibres fulfilled exacting market criteria.In final thought, the Optical Fibre Diameter Analyser plays an essential duty in improving top quality control within Fibre manufacturing.

Report this wiki page